Table of Contents

Understanding the Importance of Power Inductors in Modern Electronics

In the world of electronics, there are numerous components that play a crucial role in ensuring the smooth functioning of devices. One such component is the power inductor. Power inductors are widely used in various industries, including automotive, telecommunications, and consumer electronics. In this article, we will explore the different aspects of power inductors and their significance in modern electronic devices.

1. What are Power Inductors?

Power inductors, also known as coil inductors or choke coils, are passive electronic components designed to store energy in the form of a magnetic field. They are typically made of a coil of wire wound around a magnetic core. The primary purpose of a power inductor is to resist changes in current flow, thus smoothing out fluctuations and ensuring a stable supply of power.

2. The Role of Power Inductors in Power Conversion

Power inductors are essential components in power conversion circuits. They are commonly used in DC-DC converters, voltage regulators, and switching power supplies. In these applications, power inductors help regulate voltage levels, filter out noise, and improve overall power efficiency.

3. Inductor Types and Construction

There are various types of power inductors available, each designed for specific applications. Some common types include air core inductors, iron core inductors, and ferrite core inductors. The choice of core material and construction greatly affects the inductor's performance in terms of inductance, current handling capability, and resistance to saturation.

4. Inductance and Current Rating

Inductance is a crucial parameter of power inductors and determines their ability to store energy. It is measured in henries (H) and represents the inductor's ability to resist changes in current flow. The current rating, on the other hand, specifies the maximum current that an inductor can handle without significant losses or overheating.

5. Importance of Power Inductors in Filtering

Power inductors play a vital role in filtering out unwanted noise and ripple in power supply circuits. By providing high impedance to high-frequency noise, they ensure a clean and stable power supply to sensitive electronic components. This is particularly important in applications such as audio amplifiers and radio frequency (RF) circuits.

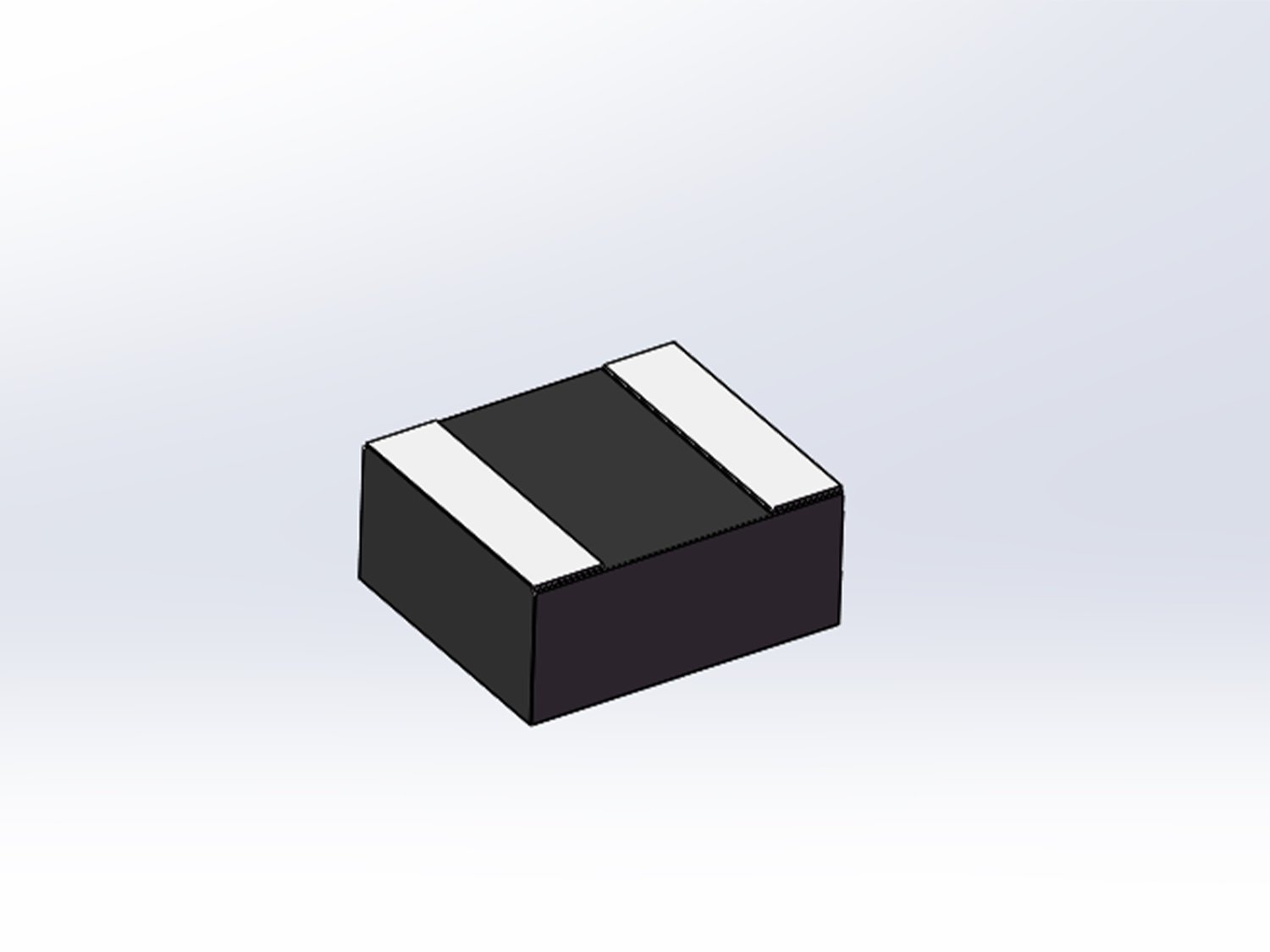

6. Impact of Inductor Size and Packaging

The physical size and packaging of power inductors have a significant impact on their performance and suitability for various applications. Smaller inductors with higher power density are often preferred in portable electronic devices where space is limited. Surface mount technology (SMT) packaging is commonly used for compact and lightweight inductors.

7. Thermal Considerations and Inductor Efficiency

Power inductors can generate heat during operation, especially when handling high currents. Therefore, thermal considerations are crucial to ensure optimal performance and reliability. Inductors with lower resistance and better thermal dissipation properties offer higher efficiency and improved overall system performance.

8. Power Inductors in Automotive Electronics

Power inductors find extensive use in automotive electronics due to the demanding operating conditions and stringent reliability requirements. They are employed in various systems, including engine control units (ECUs), power steering systems, and battery management systems. Automotive-grade inductors are designed to withstand high temperatures, vibrations, and harsh environments.

9. Emerging Trends in Power Inductor Technology

The field of power inductor technology is constantly evolving to meet the demands of modern electronics. Recent trends include the development of smaller, more efficient inductors, advancements in core materials and packaging techniques, and the integration of inductors with other passive components for space-saving solutions.

10. Choosing the Right Power Inductor for Your Application

When selecting a power inductor for a specific application, it is essential to consider factors such as inductance value, current rating, size constraints, and environmental conditions. Consulting datasheets, seeking expert advice, and evaluating different options can help ensure the optimal performance and reliability of your electronic system.