Table of Contents

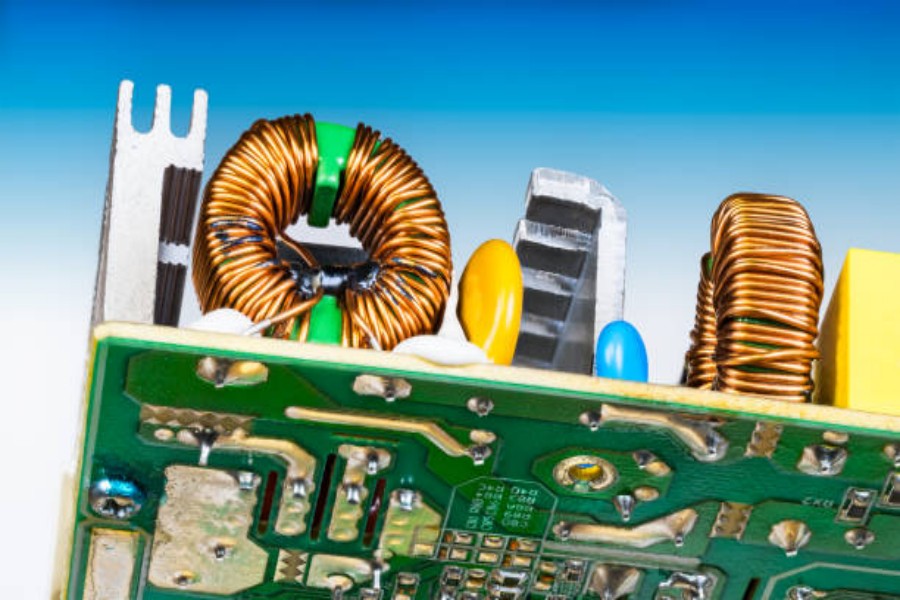

The Basics of common mode choke inductor

A common mode choke inductor is an electrical component that is used to suppress electromagnetic interference (EMI) noise in electronic circuits. This passive electronic component works by providing a low impedance path for common mode currents while blocking differential mode currents.

How Does Common Mode Choke Inductor Work?

The common mode choke inductor functions by creating a magnetic field that generates a counter electromotive force (EMF) in response to the current passing through it. This counter EMF cancels out the EMI noise, preventing any interference that may cause faults in electronic equipment. By filtering out common mode noise, this component helps in maintaining signal quality, improving system reliability, and extending the lifespan of the equipment.

Advantages of Common Mode Choke Inductor

There are several benefits of using common mode choke inductors in electronic circuits, including increased efficiency, reduced noise, and enhanced reliability. Some of the advantages are as follows:

- Reduces electromagnetic interference (EMI)

- Improves signal quality

- Increases equipment reliability

- Helps meet regulatory compliance standards

- Reduces equipment downtime

- Extends equipment lifespan

Applications of Common Mode Choke Inductor

The common mode choke inductor has a wide range of applications in electronics and electrical engineering, including:

- Power supplies and inverters

- Motor drives and controllers

- Lighting systems and ballasts

- Telecommunications equipment

- Audio equipment

- Networking hardware

Types of Common Mode Choke Inductor

There are two main types of common mode choke inductors: surface mount and through-hole mount. Surface mount inductors are preferred for high-speed data applications, while through-hole mount inductors are suitable for high-frequency power applications.

Factors to Consider When Choosing Common Mode Choke Inductor

When selecting a common mode choke inductor, engineers need to consider several factors, including:

- Frequency range

- Inductance value

- Maximum current capacity

- Temperature range

- Size and shape

- Mounting options

Manufacturing of Common Mode Choke Inductor

Common mode choke inductors are produced using either a winding technique or a thin-film deposition process. The winding technique is used for large inductors, while the thin-film deposition process is used for high-frequency applications.

Testing and Verification

Before being deployed in electronic systems, common mode choke inductors undergo rigorous testing to verify their performance and reliability. Standard quality tests include inductance testing, impedance testing, and temperature testing.

Conclusion

In conclusion, common mode choke inductors play a vital role in the suppression of EMI noise, which is essential for the proper functioning of electronic and electrical systems. These components are highly reliable and efficient, and their applications are diverse, ranging from audio equipment to lighting systems.