Table of Contents

The Importance of Choosing the Right inductors and transformers for power electronics

When it comes to power electronics, inductors and transformers play a crucial role in regulating power and current flow through electrical circuits. Choosing the right inductor or transformer not only ensures high efficiency and reliability of the circuit, but also avoids potential damages and safety hazards. In this guide, we will explore the some key factors in selecting the suitable inductors and transformers for advanced power electronics.

Inductors for Power Electronics: Types and Applications

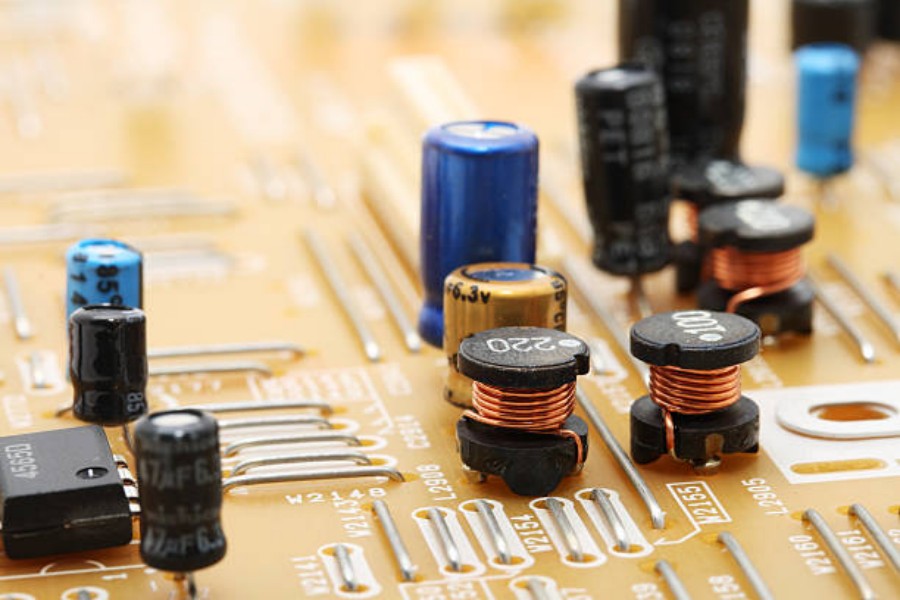

Inductors are passive components that are widely used in power electronics to store and transfer energy. The main types of inductors include air-core inductors, iron-core inductors, and toroidal inductors, each with its own advantages and drawbacks in terms of inductance, value, size, and frequency range. Some of the key applications of inductors in power electronics include noise suppression, DC power supplies, motor control, and voltage regulation.

Transformers for Power Electronics: Principles and Design

Transformers are electrical devices that enable the transfer of electrical energy between two or more circuits, usually by means of electromagnetic induction. They consist of primary and secondary windings, with the voltage and current levels depending on the turns ratio. Transformers can be designed for various purposes, such as voltage stepping up/down, isolation, impedance matching, and power transfer. Some popular types of transformers used in power electronics are flyback, forward, push-pull, and bridge transformers.

Inductor and Transformer Materials and Construction

The materials and construction of inductors and transformers can greatly affect their performance and efficiency in power electronics. Inductors may be made of copper wire, iron powder, ferrite, or other materials, depending on the requirements of inductance, frequency, and temperature range. Transformers may use cores made of iron, nickel, or cobalt alloys, with insulation and shielding options for preventing electromagnetic interference. Other factors that may impact the construction of inductors and transformers include wire gauge, winding configuration, and physical size.

Inductor and Transformer Parameters and Specifications

When selecting inductors or transformers for power electronics, it is important to consider a range of parameters and specifications to ensure proper operation and performance of the circuit. Some key parameters for inductors include inductance, rated current, resistance, and self-resonant frequency. Some key parameters for transformers include turns ratio, primary and secondary voltage/current, frequency response, and efficiency. Additionally, safety and environmental factors such as temperature, humidity, and operating conditions should be taken into account.

Design Considerations for Inductors and Transformers

Designing inductors and transformers for power electronics requires a balance between various trade-offs and considerations. For example, minimizing the size and weight of the component may lead to sacrificing some efficiency and cost-effectiveness. Similarly, optimizing the inductance or turns ratio may require careful tuning of the core and winding parameters, which can affect the thermal and electromagnetic behavior of the component. Other design factors to consider include operating frequency, load impedance, input/output voltage and current, and thermal management.

Custom vs Standard Inductors and Transformers

Depending on the specific application requirements and budget, power electronics designers may choose between using off-the-shelf or custom-made inductors and transformers. Standard components are often readily available, cost-effective, and suitable for common applications. In contrast, custom components can offer higher performance, better flexibility, and tailored characteristics that meet specific requirements such as size, shape, and material. Additionally, custom components may be optimized for certain features such as lower noise, higher efficiency, or extended lifespan.

Testing and Validation of Inductors and Transformers

After selecting or designing inductors and transformers for a power electronics circuit, it is important to perform testing and validation to ensure their proper function and reliability. Testing can include measuring various parameters such as inductance, capacitance, resistance, and thermal behavior, using different methods such as LCR meters, oscilloscopes, and thermal imagers. Validation can involve simulating the component performance using software tools such as SPICE or FEM, and comparing the results with the expected behavior and specifications. Additionally, real-world testing under various operating conditions and loads may be necessary to ensure safe and consistent operation.

Current Trends and Developments in Inductors and Transformers for Power Electronics

As power electronics continue to evolve and expand into various sectors such as automotive, renewable energy, and smart grids, the demand for advanced inductors and transformers has increased. Some recent trends and developments in this field include the use of new materials such as wide-bandgap semiconductors and high-permeability alloys, the adoption of advanced design techniques such as topology optimization and multi-objective optimization, and the integration of smart features such as wireless monitoring and control. Additionally, the need for more compact, energy-efficient, and reliable components has driven the development of miniaturized transformers and planar inductors, as well as the exploration of new manufacturing methods such as 3D printing and MEMS.

The Future of Inductors and Transformers in Power Electronics

As power electronics continue to revolutionize various industries and applications, the role of inductors and transformers will remain critical in enabling efficient and reliable power transfer and regulation. The future of inductors and transformers is likely to involve further advancements in materials, design, and integration, as well as the integration with other electronic devices such as capacitors and resistors. Moreover, as the demand for high-power, high-frequency, and high-reliability components increases, the development of new testing and validation methods, as well as new standards and regulations, will become more important.