Table of Contents

How does a molding power choke compare to other types of power chokes?

Introduction:

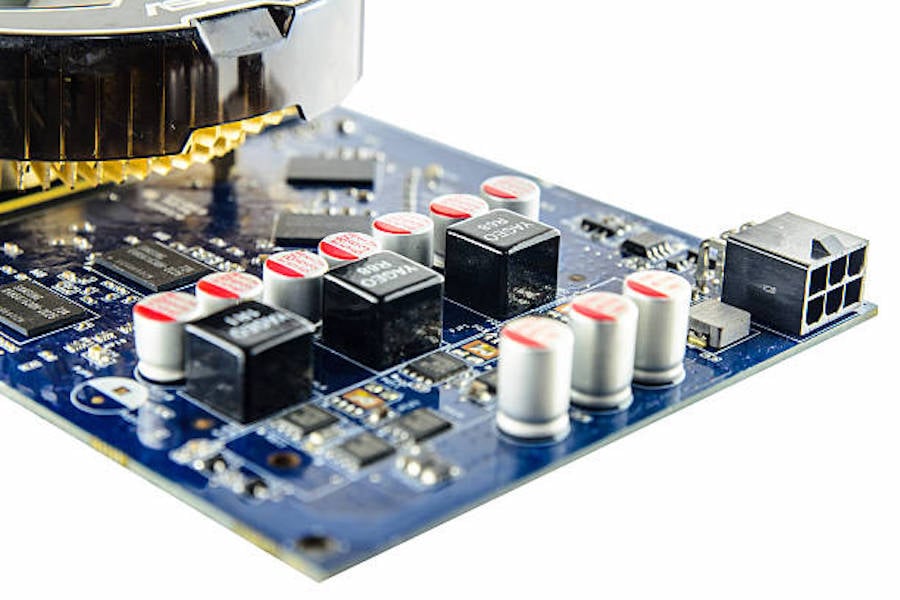

Power chokes are essential components in various electronic devices and systems. They help regulate the flow of electrical current and ensure stable and efficient operation. Among the different types of power chokes available, molding power chokes have gained significant popularity. In this article, we will explore how molding power chokes compare to other types of power chokes in terms of their design, performance, and applications.

1. Design and Construction

Molding power chokes, as the name suggests, have a unique design that involves molding the core material with resin or plastic. This construction method offers several advantages over other types of power chokes. Firstly, the molding process allows for precise control over the shape and dimensions of the choke, leading to improved performance and reliability. Additionally, the molding process protects the core material from external factors such as moisture, dust, and vibration, enhancing the overall durability of the power choke.

2. Inductance and Current Rating

When comparing molding power chokes to other types of power chokes, it is crucial to consider their inductance and current rating. Molding power chokes generally have higher inductance values, which means they can handle larger currents without saturating. This makes them suitable for applications that require high power handling capabilities, such as power supplies for industrial equipment or electric vehicles. Other types of power chokes may have lower inductance and current ratings, limiting their suitability for high-power applications.

3. Efficiency and Performance

In terms of efficiency and performance, molding power chokes offer several advantages. The precise design and construction of molding power chokes lead to lower core losses and improved magnetic coupling, resulting in higher overall efficiency. This improved efficiency translates to reduced power dissipation and heat generation, allowing for more compact and reliable designs. Other types of power chokes may exhibit higher power losses and lower efficiency, making them less suitable for applications where energy efficiency is critical.

4. EMI Suppression and Noise Filtering

Molding power chokes excel in electromagnetic interference (EMI) suppression and noise filtering. The resin or plastic used in their construction acts as a shield, effectively reducing external electromagnetic interference and noise. This makes molding power chokes ideal for applications that require high levels of EMI suppression, such as audio equipment or sensitive electronic devices. Other types of power chokes may not offer the same level of EMI suppression, making them less suitable for noise-sensitive applications.

5. Size and Weight

When it comes to size and weight, molding power chokes have a distinct advantage over other types of power chokes. The molding process allows for compact and lightweight designs, making them suitable for space-constrained applications. Other types of power chokes, such as toroidal or bobbin chokes, may be bulkier and heavier, limiting their use in compact electronic devices or portable equipment.

6. Temperature and Thermal Performance

Molding power chokes exhibit excellent thermal performance due to their efficient design and construction. The resin or plastic molding provides additional insulation and thermal dissipation, allowing the choke to operate at higher temperatures without compromising its performance or reliability. This makes molding power chokes suitable for applications that require reliable operation in harsh environments or under high-temperature conditions. Other types of power chokes may not offer the same level of thermal performance, making them less suitable for demanding applications.

7. Cost Considerations

Cost is often a crucial factor when selecting power chokes for a particular application. Molding power chokes, although they offer numerous advantages, may be slightly more expensive compared to other types of power chokes. The additional cost is justified by their superior performance, reliability, and durability. However, for cost-sensitive applications where the specific advantages of molding power chokes are not essential, other types of power chokes may provide a more economical solution.

8. Applications

Molding power chokes find applications in a wide range of industries and devices. Their superior performance and characteristics make them suitable for high-power applications, such as power supplies for industrial machinery, electric vehicles, renewable energy systems, and telecommunications equipment. Additionally, their excellent EMI suppression capabilities make them ideal for noise-sensitive applications, including audio equipment, medical devices, and sensitive electronic instruments.

9. Comparison with Other Types of Power Chokes

When comparing molding power chokes to other types of power chokes, it is essential to consider the specific requirements and constraints of the application. While molding power chokes offer several advantages, such as precise design, high inductance, improved efficiency, and excellent EMI suppression, other types of power chokes may be more suitable in certain scenarios. Toroidal chokes, for example, are known for their low magnetic leakage and suitability for high-frequency applications. Bobbin chokes, on the other hand, offer flexibility in design and winding configurations. Therefore, a comprehensive evaluation of the application's needs is crucial in selecting the most appropriate power choke type.

10. Conclusion

In conclusion, molding power chokes offer numerous advantages compared to other types of power chokes. Their unique design and construction result in improved performance, reliability, and durability. With higher inductance values, better efficiency, excellent EMI suppression capabilities, and compact size, molding power chokes are ideal for a wide range of applications. However, it is essential to carefully evaluate the specific requirements of each application and consider the trade-offs between different power choke types to make an informed decision.