Table of Contents

Everything You Need to Know About mini molding choke

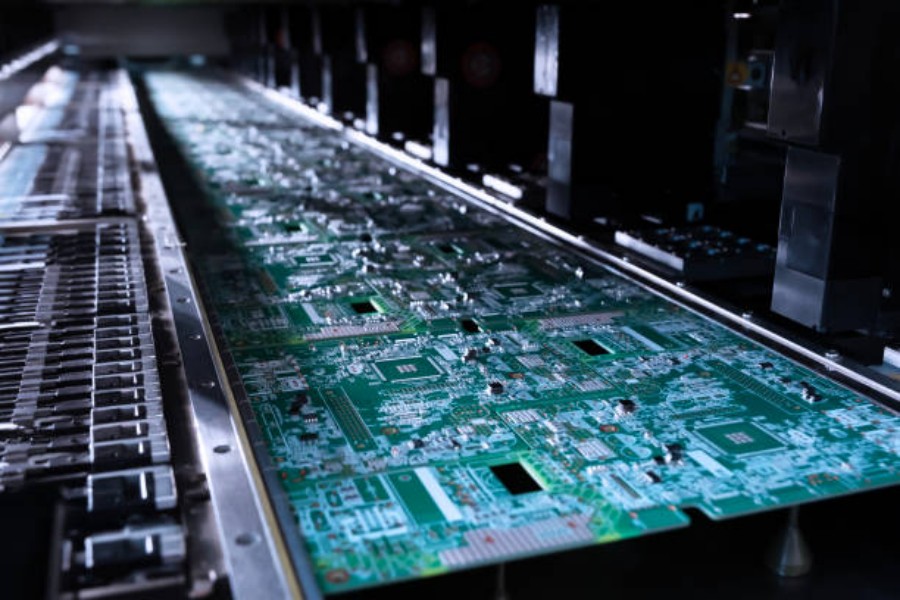

Mini molding choke, also known as miniature common mode filter choke, is widely used in various applications to filter out unwanted electromagnetic interference (EMI) and radio frequency interference (RFI). It plays a crucial role in ensuring the safety and reliability of electronic devices. Here's a closer look at the different prospects of mini molding choke.

What is Mini Molding Choke and How it Works?

Mini molding choke is a type of inductance component designed to minimize EMI and RFI in electronic circuits. It works by creating a magnetic field that opposes the flow of high-frequency signals or noise, effectively suppressing their effects on nearby components. Mini molding choke is typically constructed with wound copper wire around a magnetic core and encapsulated with an epoxy or plastic material for durability and protection.

The Benefits of Mini Molding Choke

Mini molding choke offers several benefits, including:

- Effective EMI/RFI suppression

- Small size and lightweight

- Low DC resistance and high inductance

- Wide operating temperature range

- Cost-effective and versatile

The Applications of Mini Molding Choke

Mini molding choke is widely used in various electronic applications, including:

- DC-DC converters

- LED lighting

- Switching power supplies

- Battery chargers

- Audio equipment

- Automotive electronics

The Types of Mini Molding Choke

There are two main types of mini molding choke:

- Differential mode choke

- Common mode choke

Differential mode choke is used to filter out noise that occurs between two signal lines, while common mode choke is used to filter out noise that occurs between a signal line and a ground line. Both types of mini molding choke have their specific applications and performance characteristics.

The Selection Criteria of Mini Molding Choke

When selecting a mini molding choke, consider the following factors:

- Inductance value

- Current rating

- DC resistance

- Saturation current

- Operating temperature range

- Package size and mounting type

The Installation of Mini Molding Choke

Mini molding chokes can be installed easily using through-hole or surface mount technology. It is important to follow the manufacturer's recommended guidelines to ensure proper placement and clearance to avoid any interference or damage to other components.

The Testing and Troubleshooting of Mini Molding Choke

Testing and troubleshooting mini molding choke involve measuring the inductance value, DC resistance, and current rating using a multimeter or LCR meter. If the measured values are outside the specified range, it may indicate a defective or damaged component that needs to be replaced.

The Maintenance and Replacement of Mini Molding Choke

Mini molding choke requires minimal maintenance. However, if it shows signs of physical damage or performance degradation, it may need to be replaced. Make sure to use the correct replacement component with the same specifications and package size.

The Future of Mini Molding Choke

Mini molding choke is an essential component in modern electronic devices, and its demand is expected to increase with the growing adoption of IoT, smart homes, and electric vehicles. Manufacturers are continuously improving the design and performance of mini molding choke to meet the evolving technology needs of the industry.